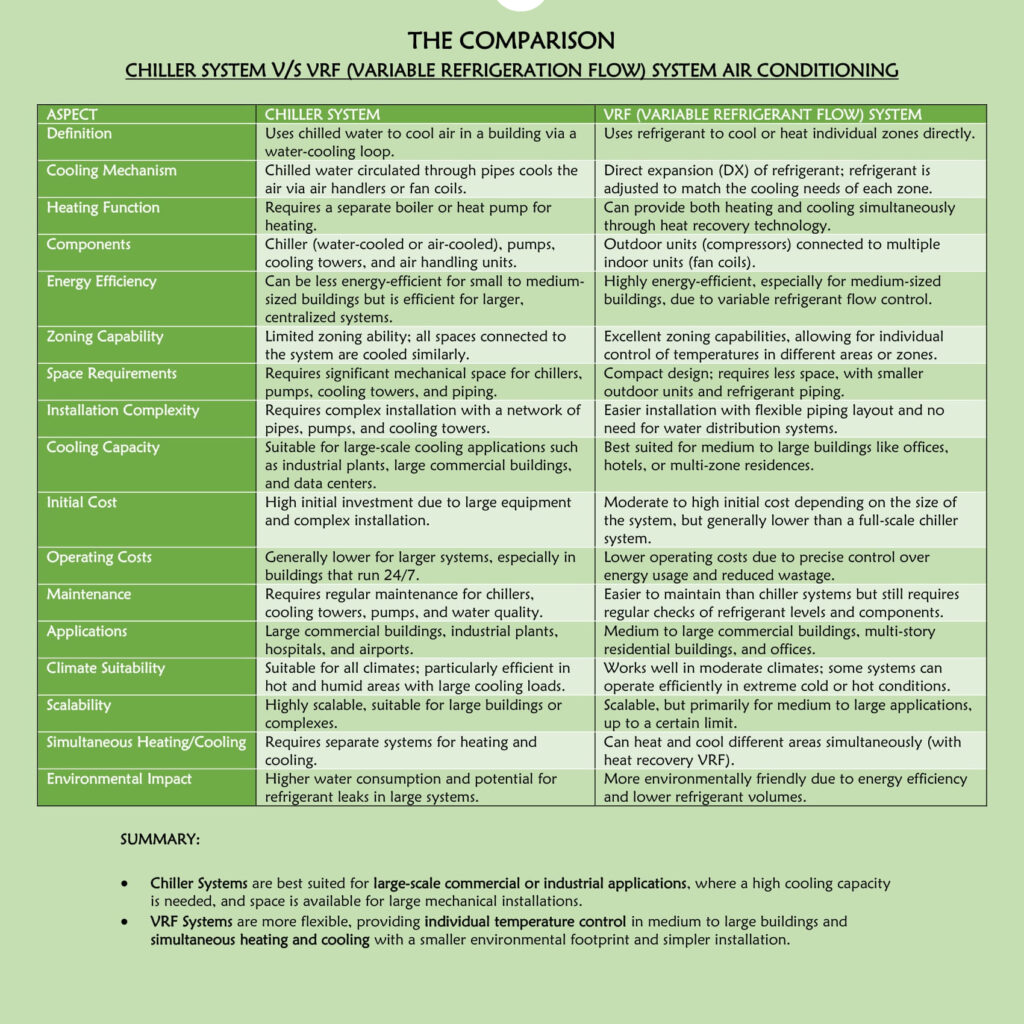

CHILLER SYSTEM V/S VRF (VARIABLE REFRIGERATION FLOW) SYSTEM AIR CONDITIONING:

| ASPECT | CHILLER SYSTEM | VRF (VARIABLE REFRIGERANT FLOW) SYSTEM |

| Definition | Uses chilled water to cool air in a building via a water-cooling loop. | Uses refrigerant to cool or heat individual zones directly. |

| Cooling Mechanism | Chilled water circulated through pipes cools the air via air handlers or fan coils. | Direct expansion (DX) of refrigerant; refrigerant is adjusted to match the cooling needs of each zone. |

| Heating Function | Requires a separate boiler or heat pump for heating. | Can provide both heating and cooling simultaneously through heat recovery technology. |

| Components | Chiller (water-cooled or air-cooled), pumps, cooling towers, and air handling units. | Outdoor units (compressors) connected to multiple indoor units (fan coils). |

| Energy Efficiency | Can be less energy-efficient for small to medium-sized buildings but is efficient for larger, centralized systems. | Highly energy-efficient, especially for medium-sized buildings, due to variable refrigerant flow control. |

| Zoning Capability | Limited zoning ability; all spaces connected to the system are cooled similarly. | Excellent zoning capabilities, allowing for individual control of temperatures in different areas or zones. |

| Space Requirements | Requires significant mechanical space for chillers, pumps, cooling towers, and piping. | Compact design; requires less space, with smaller outdoor units and refrigerant piping. |

| Installation Complexity | Requires complex installation with a network of pipes, pumps, and cooling towers. | Easier installation with flexible piping layout and no need for water distribution systems. |

| Cooling Capacity | Suitable for large-scale cooling applications such as industrial plants, large commercial buildings, and data centers. | Best suited for medium to large buildings like offices, hotels, or multi-zone residences. |

| Initial Cost | High initial investment due to large equipment and complex installation. | Moderate to high initial cost depending on the size of the system, but generally lower than a full-scale chiller system. |

| Operating Costs | Generally lower for larger systems, especially in buildings that run 24/7. | Lower operating costs due to precise control over energy usage and reduced wastage. |

| Maintenance | Requires regular maintenance for chillers, cooling towers, pumps, and water quality. | Easier to maintain than chiller systems but still requires regular checks of refrigerant levels and components. |

| Applications | Large commercial buildings, industrial plants, hospitals, and airports. | Medium to large commercial buildings, multi-story residential buildings, and offices. |

| Climate Suitability | Suitable for all climates; particularly efficient in hot and humid areas with large cooling loads. | Works well in moderate climates; some systems can operate efficiently in extreme cold or hot conditions. |

| Scalability | Highly scalable, suitable for large buildings or complexes. | Scalable, but primarily for medium to large applications, up to a certain limit. |

| Simultaneous Heating/Cooling | Requires separate systems for heating and cooling. | Can heat and cool different areas simultaneously (with heat recovery VRF). |

| Environmental Impact | Higher water consumption and potential for refrigerant leaks in large systems. | More environmentally friendly due to energy efficiency and lower refrigerant volumes. |

SUMMARY:

- Chiller Systems are best suited for large-scale commercial or industrial applications, where a high cooling capacity is needed, and space is available for large mechanical installations.

- VRF Systems are more flexible, providing individual temperature control in medium to large buildings and simultaneous heating and cooling with a smaller environmental footprint and simpler installation.